Energy & Critical Metals

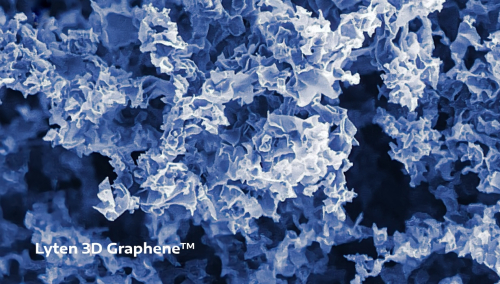

Stellantis invests in Lyten; 3D Graphene and Li-S EV battery technology

Stellantis Ventures, the corporate venture fund of Stellantis, has invested in materials innovation and applications company Lyten to accelerate the commercialization…

Stellantis Ventures, the corporate venture fund of Stellantis, has invested in materials innovation and applications company Lyten to accelerate the commercialization of Lyten 3D Graphene applications for the mobility industry, including the LytCell Lithium-Sulfur EV battery (earlier post), lightweighting composites, and novel on-board sensing.

Lyten uses proprietary reactor technology which evolved from the semiconductor industry to transform methane into carbon and hydrogen.

The carbon is permanently sequestered in the form of three-dimensional graphene, eliminating CO2 emissions.

With three dimensions, Lyten is able to tune for multiple properties in a single Lyten 3D Graphene material. The first three applications for which Lyten is tuning commercially are batteries, composites and sensors.

Unlike traditional lithium-ion batteries, Lyten’s Lithium-Sulfur batteries do not use nickel, cobalt, or manganese, resulting in an estimated 60% lower carbon footprint than today’s best-in-class batteries and a pathway to achieve the lowest emissions EV battery on the global market.

Raw materials for Lithium-Sulfur batteries have the potential to be sourced and produced locally, in North America or Europe, enhancing regional supply sovereignty. This technology will meet the needs of industries seeking lightweight and energy-dense batteries that are free from supply chain disruptions.

Among the automotive product innovations being transformed by Lyten 3D Graphene are Lithium-Sulfur batteries with the potential to deliver more than twice the energy density of lithium-ion, payload-improving lightweighted vehicle composites, and new modes of sensing that do not require chips, batteries or wires. We are committed to advancing each of these applications to Stellantis and the automotive market.

Unlike two-dimensional forms of graphene, the production of our tunable Lyten 3D Graphene has been independently verified to be carbon-neutral at scale. We are converting greenhouse gases into a new class of high-performance, high-value carbon materials and are incorporating these tuned materials into applications that will decarbonize the hardest to abate sectors on the planet.

—Dan Cook, president and CEO of Lyten

Lyten’s Lithium-Sulfur battery, composites, and sensor technologies are initially being produced on its 145,000 square foot campus in Silicon Valley. Apart from producing EV batteries, Lyten is working with previous customers to start delivering Lithium-Sulfur batteries and 3D Graphene-infused composites for specialty markets in 2023. Lyten is collaborating with its strategic investors from across multiple industries to apply Lyten 3D Graphene materials to decarbonize additional, carbon intensive sectors beyond transportation, with more announcements planned for later this year.

Stellantis launched Stellantis Ventures in 2022 as a venture capital fund committed to investing in early and later-stage startup companies developing innovative and sustainable technologies within the automotive and mobility sectors. Stellantis Ventures, powered by an initial €300 million in funding, is a key component of the company’s Dare Forward 2030 strategic plan, which sets out core targets for Stellantis, including deep emission cuts to slash CO2 in half by 2030, benchmarking the 2021 metrics, and achieving carbon net zero by 2038 with single-digit percentage compensation of the remaining emissions.

Uranium Exploration Company Announces Additional Staking in the Athabasca Basin

Source: Streetwise Reports 12/22/2023

Skyharbour Resources Ltd. announced an update from its Canada-based Falcon Project along with additional…

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla Launches New Mega Factory Project In Shanghai, Designed To Manufacture 10,000 Megapacks Per Year

Tesla has launched a new mega factory…

Giving thanks and taking stock after “a remarkable year”

An end-of-year thank you to our readers, industry colleagues and advertisers before Electric Autonomy breaks from publishing until Jan. 2

The post Giving…