Uncategorized

Suddenly, AML3D is scoring big with the US Navy as it pivots business strategy

AML3D is now focusing on selling its machines and tech rather than contract manufacturing – and it’s working, with a … Read More

The post Suddenly, AML3D…

- AML3D is now focusing on selling its machines and tech rather than contract manufacturing

- Company secures US Navy deal as Biden Administration moves to rebuild manufacturing capabilities

- Australian Defence Strategic Review and AUKUS providing opportunities for growth with defence a key vertical

AML3D (ASX:AL3) is disrupting metal part supply chains using its patented Wire Additive Manufacturing (WAM) process, which is proving to be big business as it secures lucrative contracts, including with the US Department of Defence.

Speaking with Stockhead, AL3 CEO Ryan Millar said the Adelaide-headquartered AL3 has pivoted from being a supplier of 3D metal parts to now providing its original equipment manufacturing (OEM) machines and technology.

While it is a big change for AL3, it is paying off as the company taps into the lucrative North American market as the Biden Administration looks to renew the US’s manufacturing capabilities using the latest tech.

From a PhD to business idea

First a little background. AL3 was founded in 2014 by Andy Sales, who headed the company up until September 2021 when Millar took over as CEO.

Sales is now the chief technical officer of AL3 and cleverly combined his understanding of welding and metal deposition with the emerging field of robotics to start the company.

“Andy was doing a Master’s degree and a PhD at Cranfield University in the UK and they were early innovators of using advanced robotics and software to combine that with welding systems to deposit metals into various shapes,” Millar said.

“That is the birth of the additive manufacturing from a direct energy deposition process.”

AL3 listed on the ASX in April 2020, during the early days of the Covid-19 pandemic.

Millar said the company’s patented wire additive manufacturing focuses on making large parts for industrial purposes.

“We occupy a niche and inside that niche there are very few players who do what we do,” he said.

“Additive manufacturing is a much more economical way to manufacture parts.”

What is additive manufacturing

Time for a little engineering 101. Millar said traditional forms of manufacturing components and structures include casting, forging or subtractive manufacturing, where you get a big block of titanium, aluminium or steel for example and carve out a part through machining.

He said additive manufacturing is making that part almost to the size required. It’s known as near net shape (NNS) manufacturing.

“One of the amazing things about manufacturing with metal as opposed to a polymer of some sort is each metal melts at a different temperature,” he said.

“Copper melts at a different temperature to steel or titanium so as you are depositing this metal you need to have a deep scientific understanding of the properties of different metals.

“Understanding all that is Andy’s skillset and that is a key part of building parameters within our software.”

Building on its unique expertise the company has established relationships with universities and scientific organisations including Flinders University, Deakin University, RMIT and the CSIRO.

Looking for growth opportunities

With extensive experience in the tech space, Millar came on as CEO after consulting to AL3’s board to try to understand its growth opportunities.

He started researching whether companies wanted AL3 to manufacture parts or were more interested in purchasing their machines and technology.

The patented machine called ARCEMY is a 3D metal printer, which comes in a range of different sizes and options.

The patented WAM process, combines an electric arc with certified welding wire, as feedstock, to produce medium to large scale, free-form parts.

“ARCEMY is essentially a very large robot but what is driving it is the software platform and obviously the R&D inside that platform is what makes our 3D printing system different to other 3D printing systems,” Millar said.

“That’s where a lot of investments resides is with the tech roadmap more than anything else.”

Targeting the US market

Millar found companies were particularly interested in buying the machines that AML build and its technology.

“There was a pivotal point at the end of last year where I re-wrote the strategy for the business, presented it back to the board and it was heavily focused on the US market,” he said.

“The US market is about 30% of the global demand and supply of additive manufacturing parts.

“Australia is about 3% of the Asia-Pacific market, which is also tiny compared to the US market.”

Post-Covid and in a geopolitically uncertain world Millar said there has been great emphasis on rebuilding sovereign capability in the US, presenting an opportunity for AL3.

“When the Biden Administration came into office one of their big initiatives was the Additive Manufacturing Forward (AM Forward) initiative,” he said.

“It was about rebuilding the US manufacturing capabilities using advanced technologies.”

Moves to only selling OEM and tech

AL3 is now only a seller of its OEM machinery and technology, which is widely different to what they have been doing.

“But listening to the voice of the customer it’s our machines and technology which they want and logically it makes perfect sense,” Millar said.

“Being based in Adelaide trying to fulfil parts for North American customers is super challenging.”

He said furthermore there is annual recurring revenue (ARR) in terms of maintenance and support of the machines, which sell for good margins and better than that of manufacturing parts.

“You sell 10 or 15 machines in a given period of time and that maintenance and support ranging from 10% to 20% is annual recurring revenue based on software upgrades, features and so on,” he said.

Winning US contracts

The Adelaide headquarters is now used to protype various parts, such as those for the US Navy and other large-interested Tier 1 companies from different industries such as oil and gas and aerospace, where AL3 has done a reasonable amount of work.

Millar said the US Navy’s submarine programs are accelerating very quickly and not seen since World War II.

“There’s a requirement to scale-up their submarine program,” he said.

He said the AUKUS security and defence partnership formed in September 2021 between Australia, the UK, and US to enhance cooperation in areas of defence, technology, and security in the Indo-Pacific region also put pressure on to speed up manufacturing capabilities.

One of the significant aspects of the AUKUS partnership is Australia’s decision to acquire nuclear-powered submarines with help from the US and UK.

Millar said one of the best ways to build a very large part for a submarine is through 3D printing.

“Looking at which are the best 3D printers globally to do that and we are one of very few that can do that size of part they need to make,” he said.

The US Navy approached AL3 and after discussions it was decided to establish subsidiary AML3D USA.

“Operating in the US becomes a completely different world because you’re inside the country, can see designs as a subsidiary of the Australian company,” Millar said.

“It becomes a lot easier to service your customer.”

Millar said the initial sale for AL3 to the US Navy involved an ARCEMY X-Edition 6700, the largest standard system from the company’s lineup and valued at ~$1 million.

Defence a key industry vertical

Millar said AL3’s machinery and technology is designed to manufacture very large components out of “exotic alloy metals”.

“This means we can make very large things with high anti-corrosive properties, so we naturally have a good, sweet spot in the vertical of defence, navy and maritime,” he said.

“It also means oil and gas is a good vertical for us and we are also focused on the aerospace industry by history of who we have been working with and so will continue to target those verticals.”

He said as well as the US there are opportunities in the UK and Europe along with domestically, but the focus is on North America.

“We have some great opportunities here in Australia but much smaller in scale and then really big opportunities in America,” he said.

Millar said the Defence Strategic Review, considered the most significant Defence report since WWII, along with AUKUS, presents opportunities for AL3.

“Obviously AUKUS presents a phenomenal opportunity for AML3D, not even questioned,” he said.

“We fit in a very niche part, so we have an advantage to capitalise on some of the requirements for AUKUS pillar 1 which is part of the Defence Strategic Review.

“We need to position ourselves in the best possible way given we are a relatively small company.”

Backing of investors

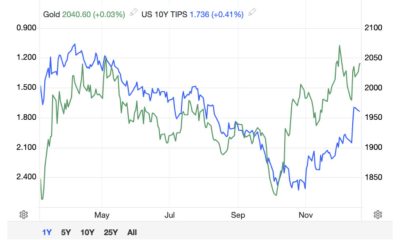

While the company has been hard hit by the tech downturn and yet to turn a profit, Millar is confident in its prospects.

AL3 recently undertook a well-supported capital raise, which included a $3 million placement to sophisticated and institutional investors.

The company received subscriptions of more than $700k for the SPP, representing an oversubscription of more than 75% above the offer size of $400,000.

“Capital raising in the market is very difficult, but we managed to raise capital quickly and easily,” Millar said.

“From our perspective we need to do what we are going to do and it’s not a case of not looking at the scoreboard; obviously I am interested in the share price.”

Millar forecasts the share price will rise longer term as the company achieves its objectives and markets improve.

“It’s not to sound arrogant or dismissive but our immediate focus is to achieve our objectives and I am confident,” he said.

The AL3 share price today:

The post Suddenly, AML3D is scoring big with the US Navy as it pivots business strategy appeared first on Stockhead.